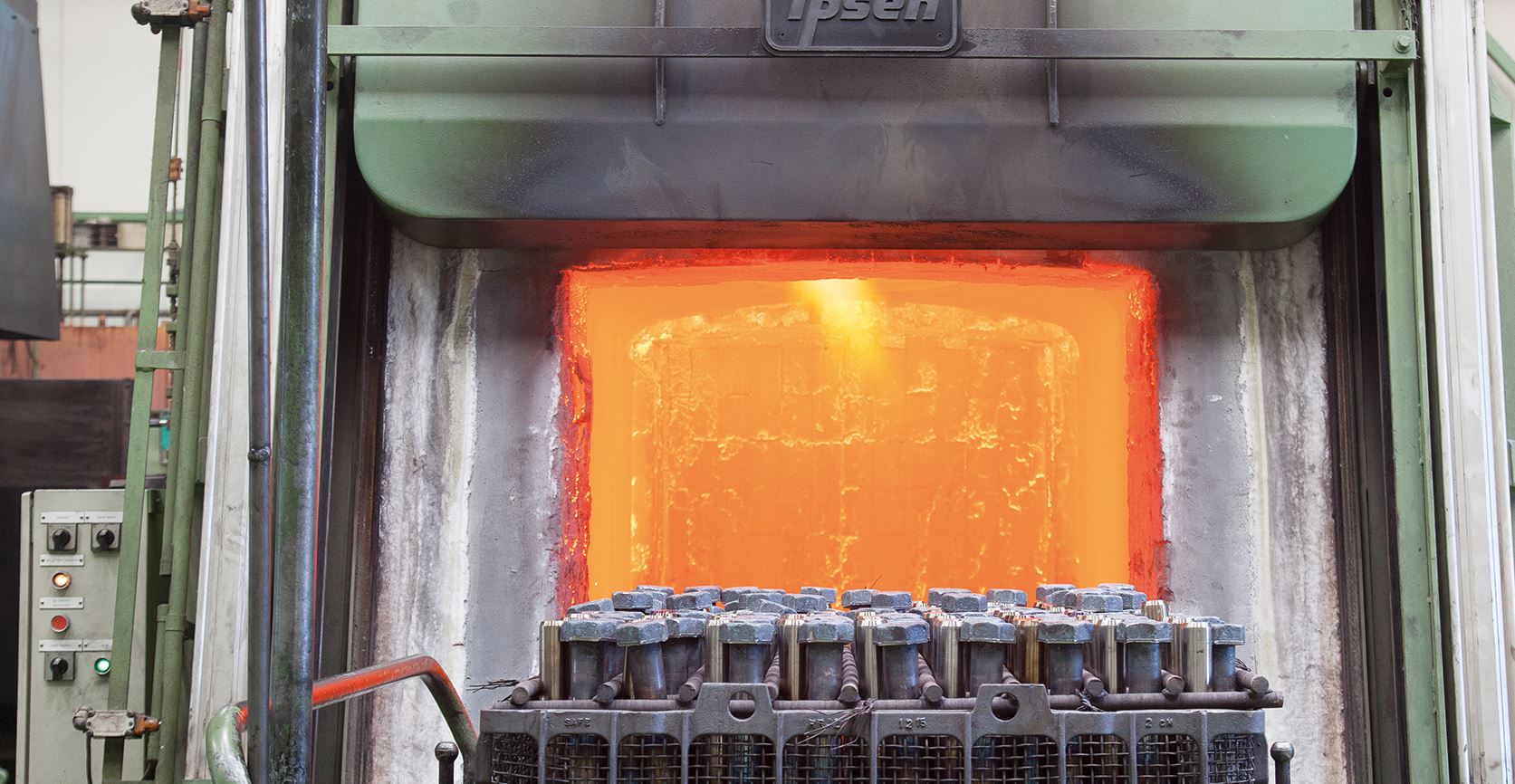

The Quenching and tempering process is a heat treatment that consist on the transformation of the structure of the steel, heating it to austenization temperatures and then cooling it quickly in a quenching medium such as oil to increase its hardness and resistance in all its section.

APLICATIONS

Carbon steels and Alloyed steels in parts that once in service will be subjected to different tensile, compression, bending and/or torsion forces.

DETALLES DEL PROCESO

TYPE OF PARTS